I’ve started my first passenger train project – a revolutionary new concept of rail travel at the time – The Challenger, train #8 between Los Angeles and Chicago. I’m modelling the first section of the consist with it’s coaches and chair cars.

Researching the Project

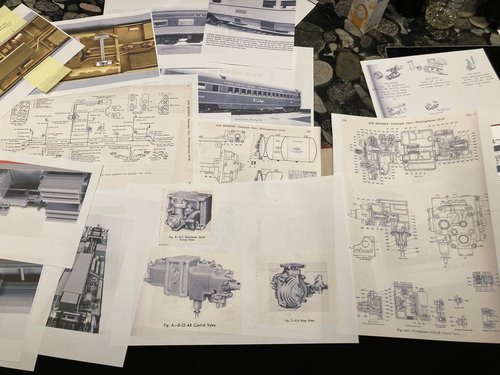

These cars were built by Pullman Standard in 1937 and amongst the first to feature brand new lightweight construction. The first step is to gather all the publications and look up the details and parts involved.

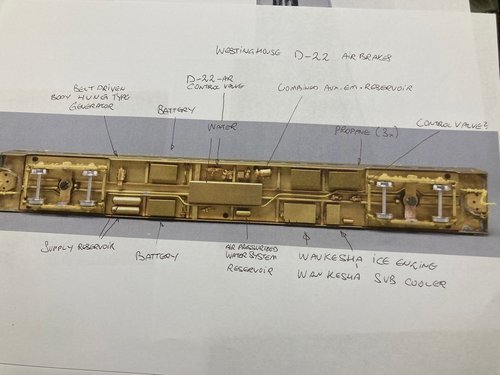

With the help of specialist and fellow modeller David Schultz I have now pictures of the underbody of NP 517, a sister car to those of the Challenger. He took tons of photos that show the air brake arrangement, generator, tanks and all the piping involved. With that knowledge I can reconstruct the underbody details of my cars. North Shore Railroad Museum

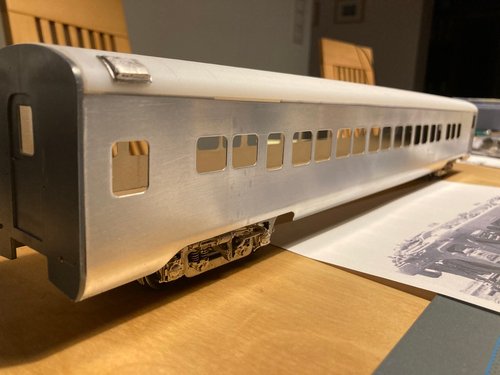

The Car Kits

Edmund Wichman of 401 Streamline Models makes these steel sided car kits. They are fantastic and I can’t wait to start woring on them. I will create a fully detailed underframe, interior and trucks. This is a huge project but I really enjoy recreating such a thing from the past that wrote transportation history.

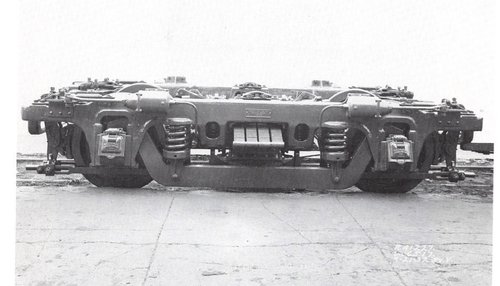

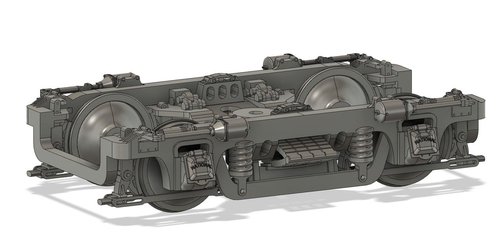

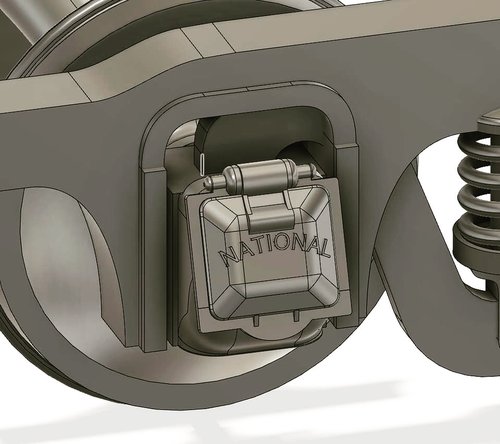

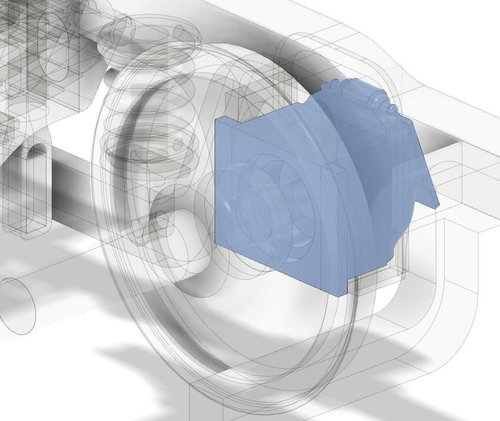

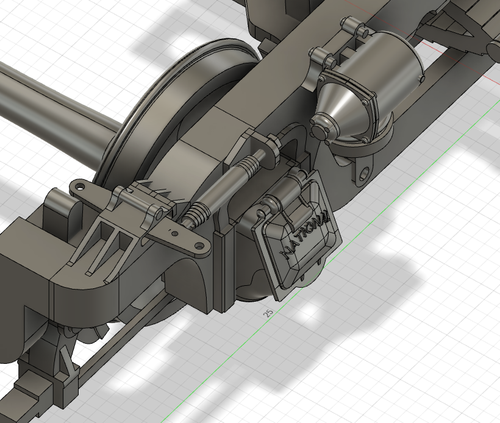

43-EG Passenger Trucks

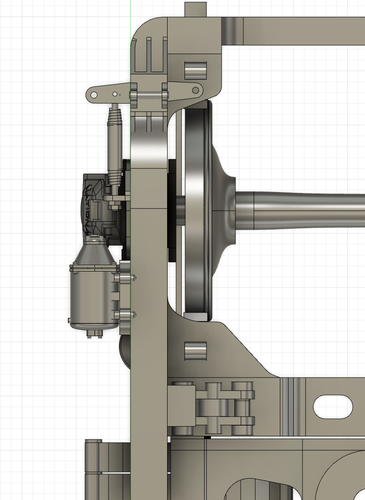

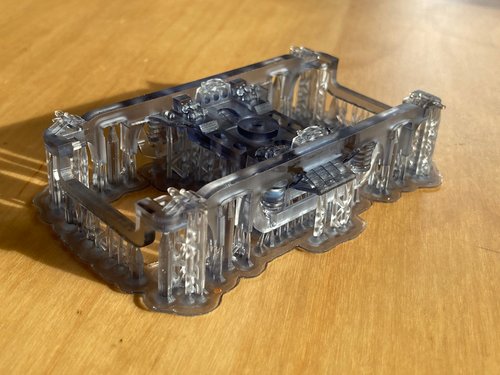

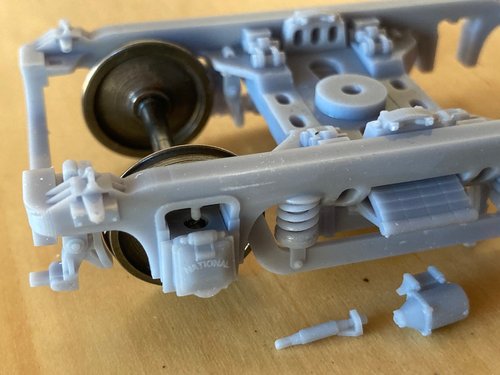

Unfortunately there are no such trucks available and so I have to make my own.Darfting is well under way and I will soon print the first test samples. Ultimately these trucks shall be cast in brass or be metal-printed or even machined. The options are there and I will see what’s best. Printing them in resin is of course an option, too. Protocraft wheel sets and ball bearings are already in stock.

Whether equalisation is going to be done prototypical via the equalizer bars or via coil spings hidden over the journal boxes is not yet desided. In any case – a good riding truck with all wheels making safe contact with the rail is the goal here. The tiny flanges of Proto:48 wheels do not allow for a lot of mistakes. The train’s name is not “The Challenger” for nothing!

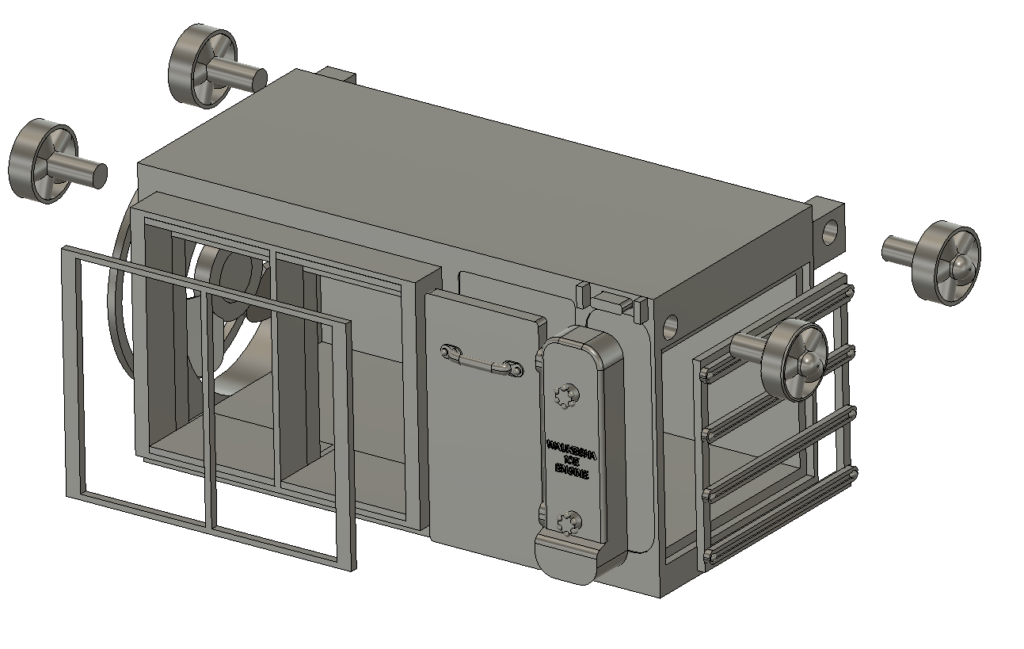

I’m in the midst of the drafting process and I realise how important it is to be really very exact when laying out the general dimensions. Everything on these components was extremely well designed to fulfill it’s funciton and to create a working geometry. Air brake rigging components might be well executed in sheet metal or even photo etchings.

The first test prints are promising and I managed to master the difficult to print ‘Siraya Tech Build’ resin. That material is strong enough to make a durable and non warping passenger truck.

Underbody Detail

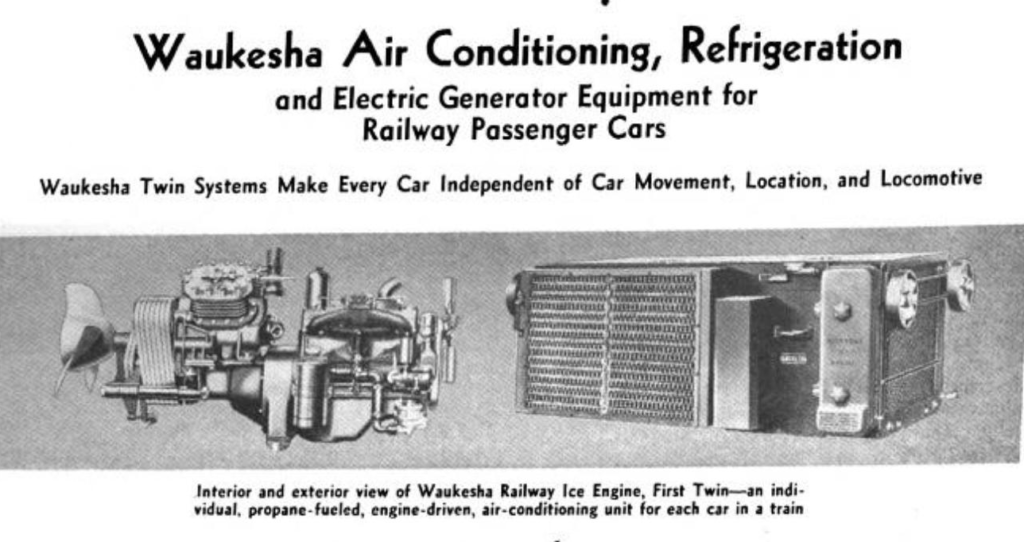

There’s a lot going on beneath the car body. I’ve started out with the Waukesha Ice Engine, the state of the art air conditioning system of the time. Powered by propane gas and thus independend of electrical power from the generator, these units were able to cool a passenger car even while sitting still at a station.

Amazing what you do really perfect I hope you saw me on Pinterest a lot of pictures from me you can see