Individual

Freight Car Parts

Improving Kits and Models

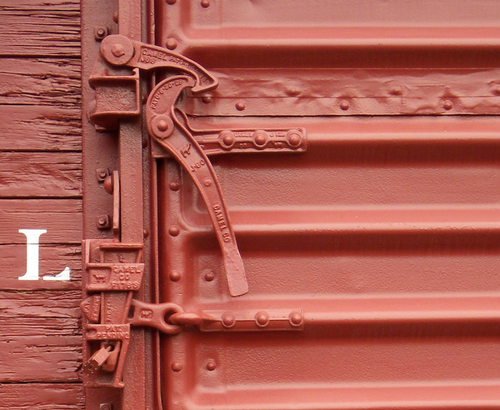

CRECO Door Hardware

An other popular manufacturer of door hardware was the Chicago Railway Equipment Company (Creco). These components can be found on many freight cars of the time, often in combination with the Superior Door.

This door latch was often used on Superior five and seven panel doors. I’ve designed the part to sit flush with the door panel. For a correct fit you might have to shim the door frame a bit.

The lift handle held the door in open or closed position and could be secured with a padlock.

Camel Co. Door Hardware

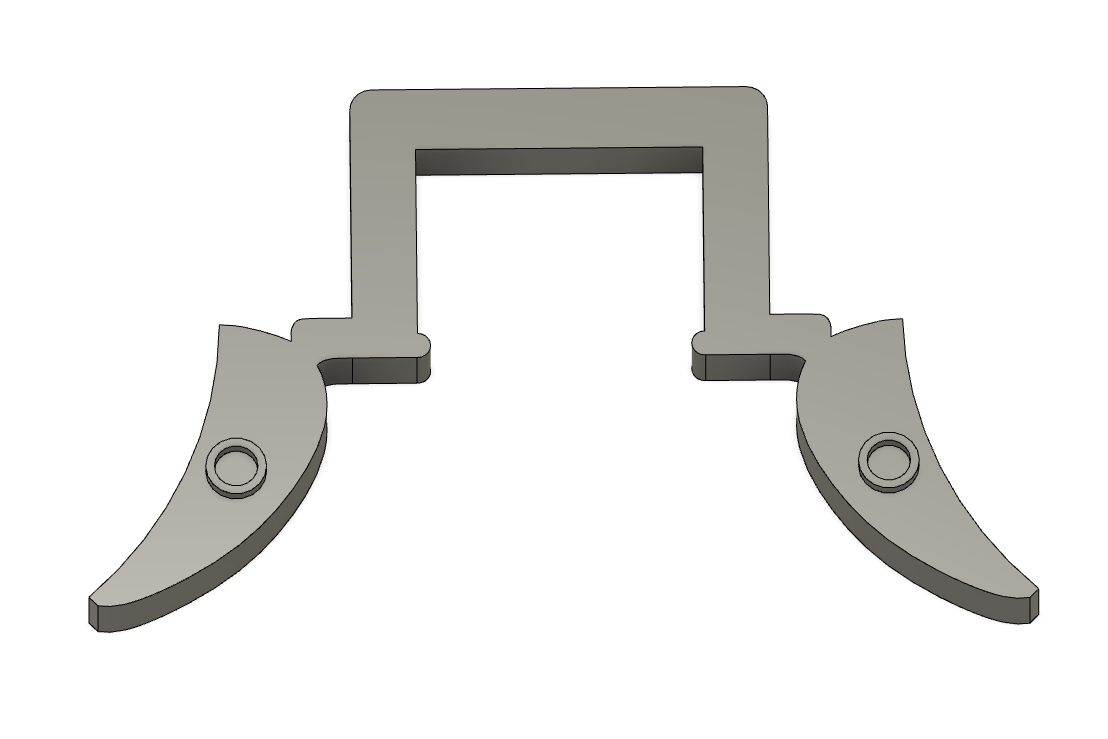

The Camel Company of Chicago was once a major supplier of railway components. It’s hook and lever door closing patent could be found on freight cars over decades.

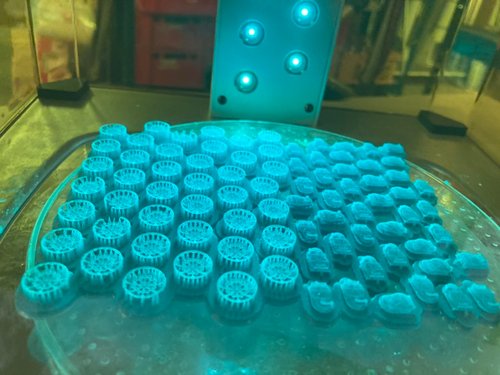

I have the Elegoo Saturn at work using standard settings and their water washable resin. Having them installed makes a great difference in detail and these tiny parts really add to realism. The molded on door lever can easily be removed with a sharp blade or a chisel. Thanks to Gene Deimling for helping me with prototype info!

I love the Intermountain plastic boxcar kits and I really have many of these. The door locking mechanism is poorly modeled. With these files you should be able to print the detail parts in resin. The two lever positions represent a tight fit and a loose fit of the closed door to add a bit of vatiation.

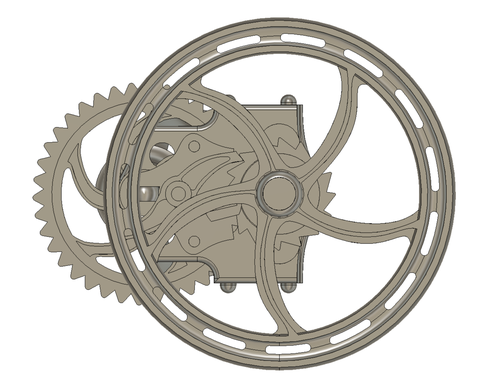

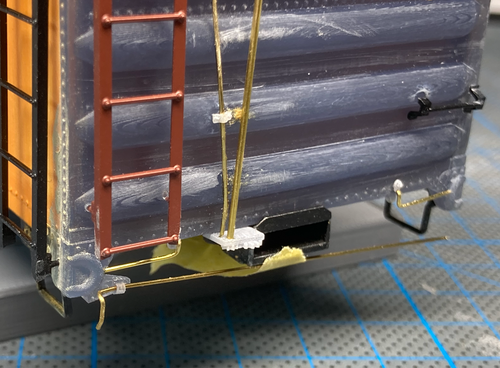

Vertical "Power" Handbrake Hardware

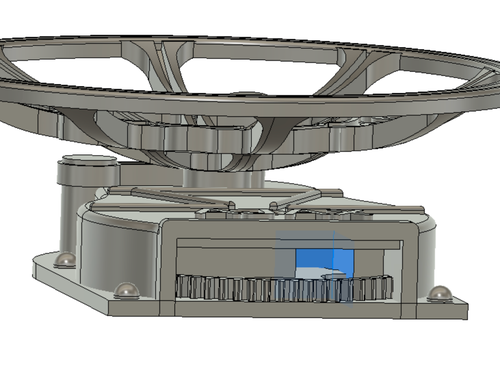

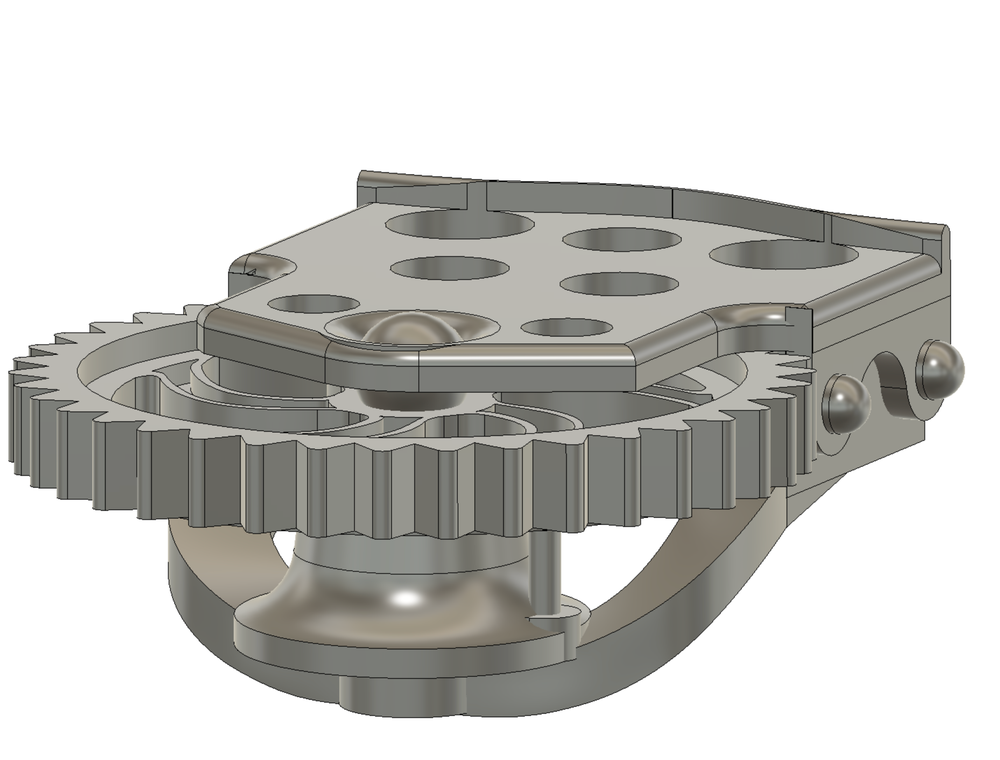

The 1930’s saw an improvement in hand brake design. Where before a chain wound up on the vertical brake staff, geared mechanisms became mandatory. A cam gear Power Brake tightened the chain to the brake cylinder, powered by a vertical brake shaft, driven by a horizontal wheel and secured by a rachet that is mounted on the brake step.

The design is optimized for a 0.8mm brass brake staff.

Handy parts when it comes to model a staff hand brake.

5 Spoke Hand Wheel, Brake Rachet, Cam Gear and 3 sizes of brackets

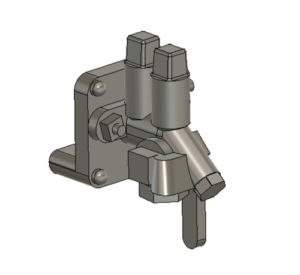

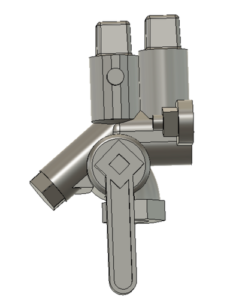

Westinghouse Dual-Pressure Retaining Valve

The Westubghoues Double-Pressure Retaining Valve is an important part of the car’s air brake equipment. It allows switch crews to manually control the brake cylinder air pressure and is mounted high on the B-end of the car to be reached from the brake step.

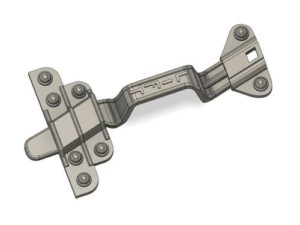

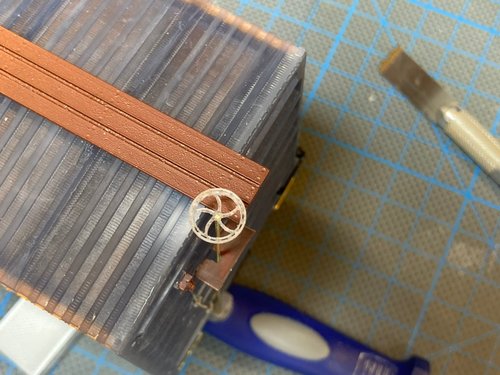

AJAX Handbrake Equipment

The Ajax Hand Brake Equipment was introduced in the early 1930’s to meet the new A.A.R. (then A.R.A) requirements in terms of safety, such as a spin-free release. It could be operated with one hand, too. My model consists of two mounting variations, one with rivets and one with hex-head screws. Please note that there’s a bit of room within the gear housing to glue a chain in place.

Please note – the wheel is an extremely fine part and hard to work with. That for I have added 3 versions to the zip-file, one at scale dimensions, a medium one with a rim height of 0.6mm and a strong wheel with a rim height of 0.8mm. You can choose the wheel that works best for you.

Miner Power Hand Brake

This very popular hand brake was produced by W. H. Miner, Inc., Chicago, Ill. It became one of the most common systems of the transition era. Different hand wheels were in use throughout the years, my model represent an early version used in the 1940’s. Like the Ajax, this hand brake could be operated with one hand. The Miner could be found on virtually every kind of railroad car – passenger to tank.

Three hand wheels are included, they differ in lettering. To really be able to read the text embossed to the wheel, you might want to keep the Z-resolution as low as 25 microns.

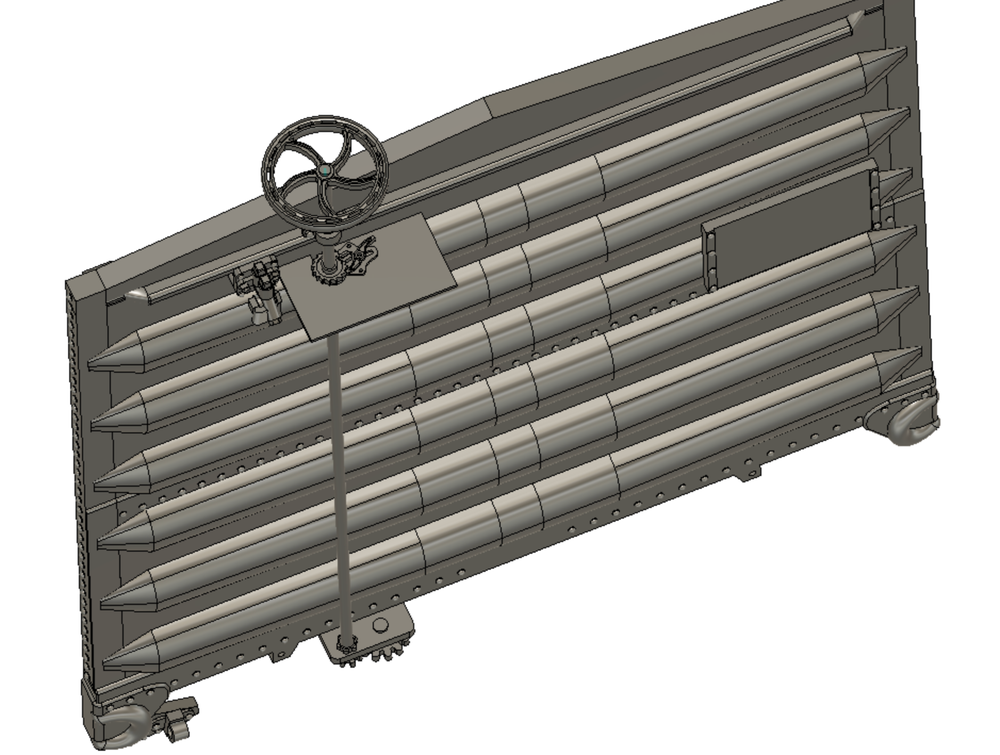

Superior Vertical Gear Power Hand Brake

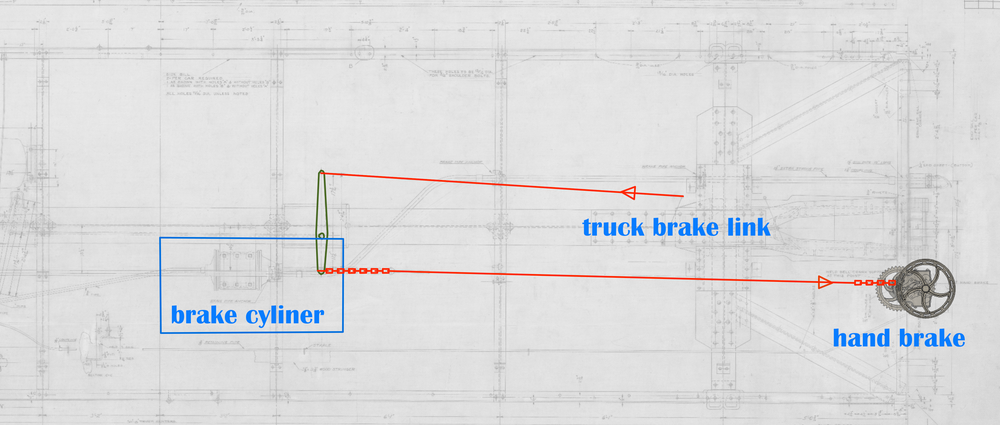

A popular variant of the countless vertical staff brakes used in the late 1920’s throughout the transition era. The design is set up for a 0.8mm brass wire to be used as a brake staff. The illustration below shows how the hand brake cam is connected to the brake cylinder via two chains and a rod. When applied, the chain is wound up into the geard cam and the brake cylinder is therefore manually applied by pulling force. The fulcrums translage this force into a pulling motion that affects the car’s trucks .

5 Spoke Hand Wheel, Brake Rachet and Cam Gear resemble this fine detailed railroad hand brake.

Brake shoes for standard freight trucks

Some freight car trucks come without brake shoes. I love the old spring loaded Athearn trucks, alas they lack brake shoes. Print them and simply snap them onto the bolster. In this case I prefer PLA over resin for this print because of it’s greater flexiblity and durability. The raised knobs could be connected with bars from side to side if you wish to model the full brake rigging. I personally don’t since this feature could hardly be seen under the model.

This little part is easy to print and snaps around the truck bolster. I use these with great success on Athearn trucks. No glue or screws needed.