Detail Parts

For the Atlas 1923 ARA Boxcar

Prototype Fidelity!

Atlas O has brought out some really fine models in the past and in vast numbers. These cars can be easily found online or at train shows. The model features the 3 panel Creco doors that are correct for most railroads who had these cars on their roster. You can add variety to your rolling stock by detailing one or two of these cars for the Chicago Great Western Railroad!

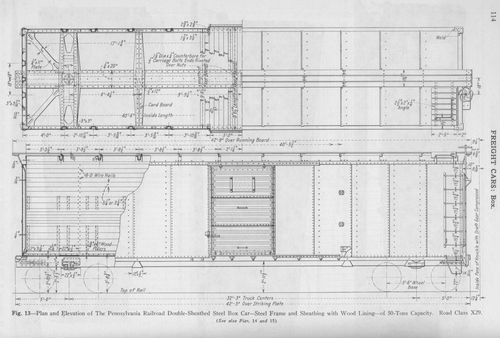

The 1923 ARA standard design boxcar was brought forward by the mighty PRR who had many thousands of the type, classed X29 by the Pennsy. This design marked the transition from wood to steel in freight car construction. in the 1930’s, more than 50.000 of the X29’s and clones of other railroads have been constructed, making it the most common type of railroad car at the time.

The much smaller Chicago Great Western railroad cloned the proven X29

design and had a total of 1500 cars of the type, built in three bunches.

Car numbers: 85000 – 85998, 8600 – 86998 and 87000 – 87998 (500 cars each, only even numbers). Consult the December 2001 issue of Railmodel Journal for more information.

A Special Door

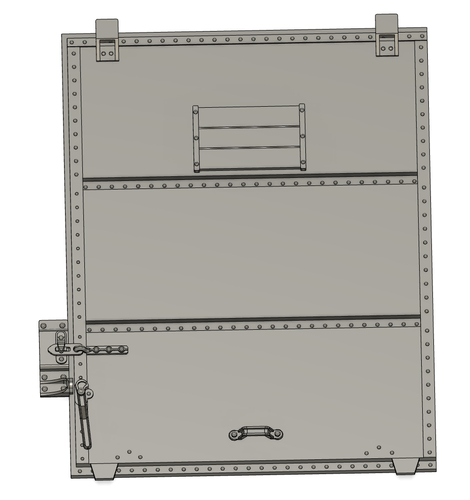

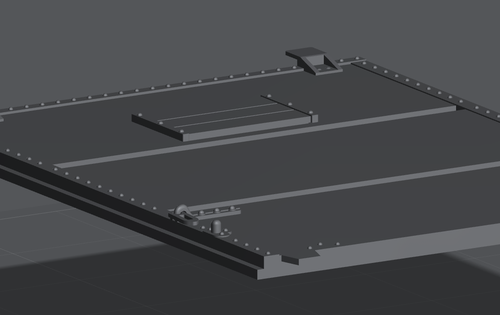

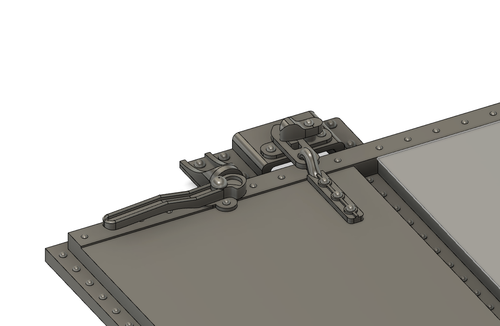

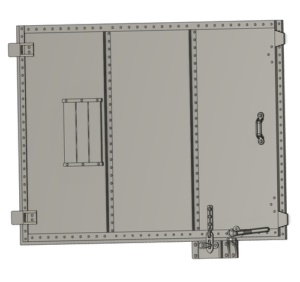

Manufactured by Pullman, these doors were often mistakenly referred to as “Reverse Creco Doors”

Understanding and designing the door hardware was quite a challange. The hasp is latched by a small pin that can be secured with a pad lock. Originally these doors had a starter (hand lever) to push the closed door open. This device disappeared on many cars over time and can be attached as needed, being a separate .3df file.

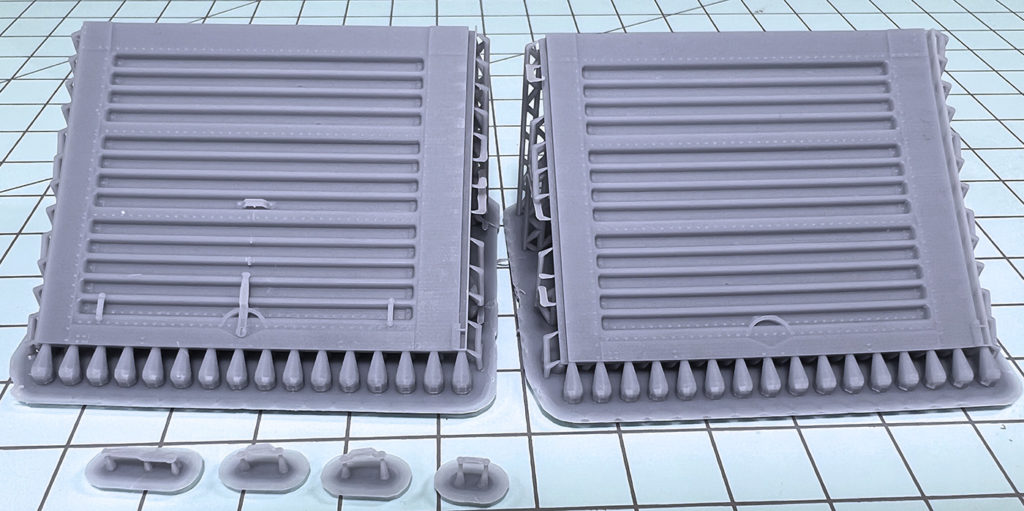

The prints snap perfectly into the car’s upper door rail. Because of Atlas’ construction specs the lower door rail sticks out just a bit too far so you could either cut away the bottom door hangers or carve out a bit of the railing. I did the latter and it looks great. I recommend super glue to fix the fully cured door into place.

The .zip files contain a reinforced version of the closed door that should not want to warp a lot. Also you have the option for an open door to be glued in place to the car body. That file is thinner and has the hasp hanging from the hasp fastener.

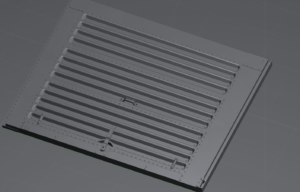

Also the he Door handle is done as a separate part. Drilling holes for these should be easy – the positions are marked on the backside of the print. The sample prints shown here are done in Elegoo Water Washable Resin using 25 micron layering height. Since there are a lot of flat surfaces involved, I recommend to carefully angle for your personal printer’s resolution. Optimized 25 micron angles on my Elegoo Saturn is 26.57 degrees while 50 microns require 45 degrees.

This one of a kind Pullman Door is specially designed for the Chicago Great Western “X29” Boxcars. Door complete with tack board and hangers, separate door handle and starter, marked drill positions on backside. Can be modelled in open or closed position.

Seaboard Airline Lumber Door Rebuilds

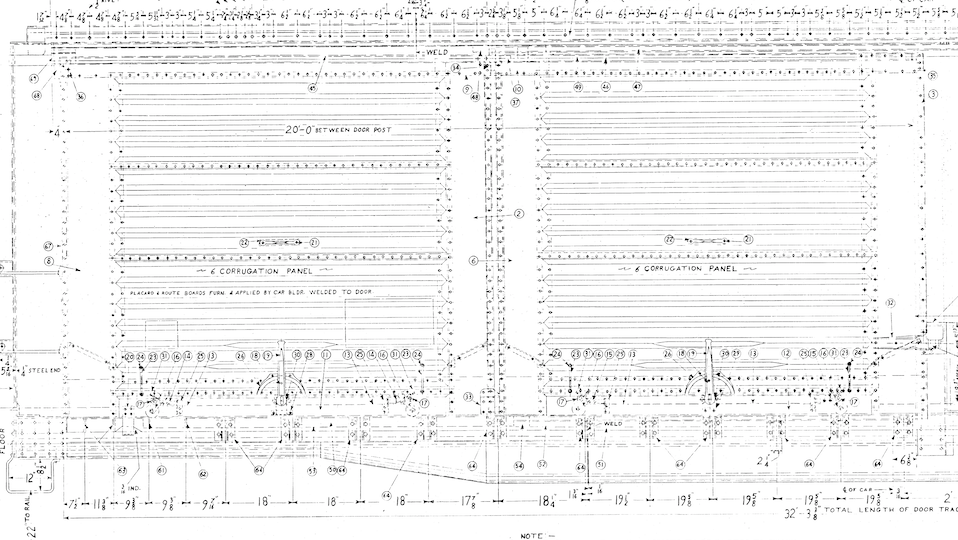

The Seaboard rebuilt a couple of it’s X29 cars with doble doors to ease lumber loading. I made this door for Mr. Edwards, who is currently kitbashing that car.

Prints by Daniel Dawdy of O-Scake Resource Magazine

The door is 10′ wide and 8’3″ high. Since I personally don’t model those later years, I don’t build such a car myself. The door is pretty exact and has been drafted from prototype plans. Two door bodies inculded – one fully equipped and the other with separate parts.