Locomotive Parts

For Diesels

Fairbanks Morse Erie Built

The Atlas O version of the Erie Builts is a mixture of a really nice plastic shell and a rather poor drive. On my ABA set of the famous Santa Fe #90 locomotives I try to improve both the Atlas drive and the cab. The powered front truck’s motor reaches all the way into the cab, ruining the appearence of the locomotive completely. My solution is to go with only one truck powered on the A-units, that leaves me with 4 out of 6 trucks powered and that works for me.

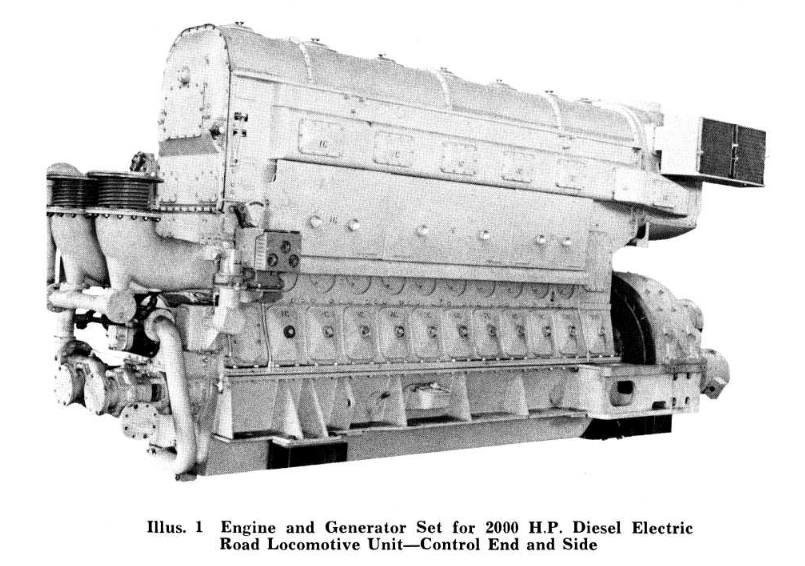

The Protoype engines were delivered in May, 1947 and featured already some improvements over the very first release of the locomotive two years earlier. Powered by the FM 38D 8-1/8 opposed pition diesel engine with an output of 2000 hp, these engines had a distinctive sound that I create with the corresponding Soundtraxx Tsunami2 Decoder.

Construction

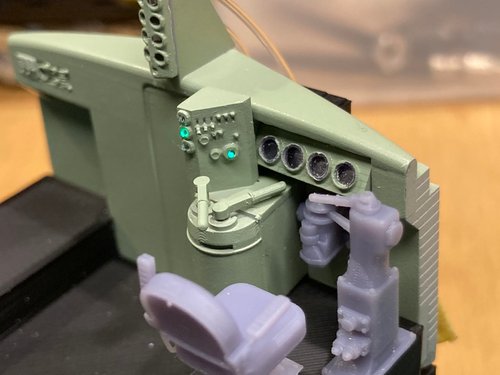

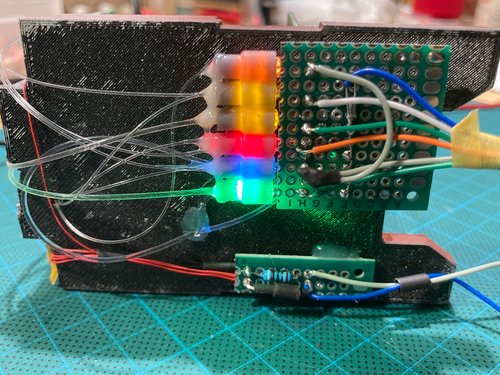

I use a composite method of both SLS and FDM prints. The structural parts are all extruded PLA while the detail parts are resin prints. I use SMD LED and light fibers to illuminate the instruments. The LED are mounted under the cab floor.

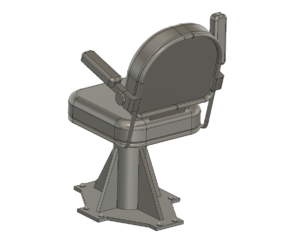

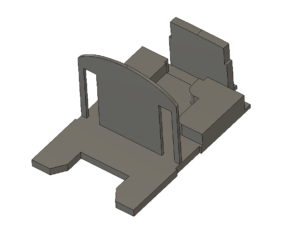

Fairbanks Morse Style Cab Seat

Four different versions of arm rest position. This file prints easiest in an upright position with light supports.

Standard Cab Seat

Five different versions of arm rest position. These seats with the round base were widely used in various locomotives of the late 1940’s and 1950’s.

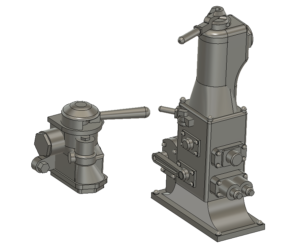

Westinghouse 24RL Brake Stand

And the corresponding independent brake valve. The equpiment was very common on the 1st generation diesels with the tall stand responsible for braking the train as a whole and the independent valve braking the engine – expressed in very simple terms.

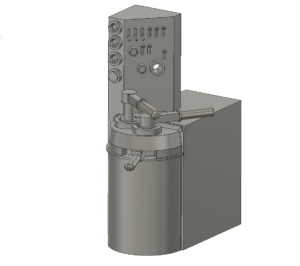

Fairbanks Morse Control Stand

This is my reconstruction of a control stand from a FM C-liner. No Erie Builts have survived and I was not able to find a fotographic evidence anywhere so I took the colsest cousin as a reference. The files are complete with two selector levers, one for directions and the other one needs to be printed twice for a throttle and the power selector.

Generator and Air Intake

Parts of the engine compartment can be seen through the side windows, mainly the generator and the air compressor. If lights are installed in the engine room, these details can be clearly seen inside the locomotive, adding a unique detail to the model.

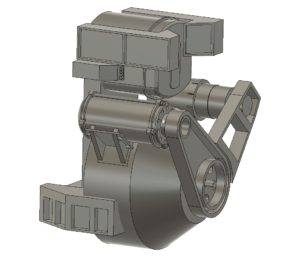

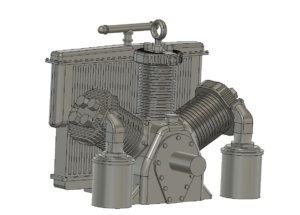

Westinghouse Air Compressor

This is an exact replica of a 3-CD Air Compressor by Westinghouse Air Brake Company of Wilmerding, PA. The mighty aggregate supplied the brake system with compressed air. parts of it can be clearly seen through the side windows.

Cab Signal

A box with four siganl indicator lights that is capable of a working cab signal system. I have two aspects lit in my locomotive – top is green and 3rd from top is yellow. The decoder automatically switches between yellow when locomotive is stopped and green when it moves. 1mm light fibers have the perfect size to light through both left and right hole.

Cockpit - FDM-Print Recommended

This is the basic structure that keeps it all together. You could print that in resin but I recommend a different material like PLA for more stability. A resin print would eventually warp and deform, to prevent this I chose the sandwich technique. Resin for the details and PLA for stabilty.

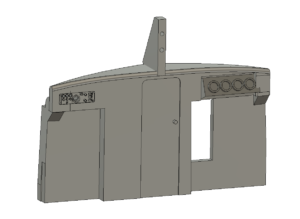

Cab Front

This essential part has been drafted to fit exactly into the Cockpit part and into the Atlas shell. The dashboard with the main control gages is a separate part that can be lit from behind when printed in clear resin.

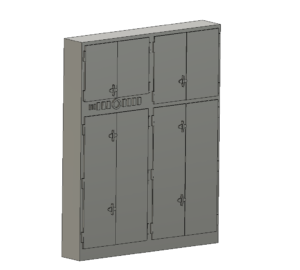

Control Compartment

Electrical fuses and relays are housed in this tall compartment located on the backside of the cab.

In the Pipeline

Currently under construction is the cab interior for the Alco SW-1 switcher offered by Glenn Guerra at sscaletrackworks.com

It’s a great brass model and I could get one with Proto:48 trucks waiting for paint and interior.